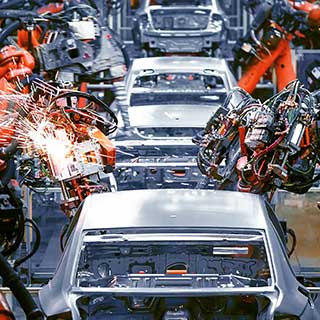

IATF 16949 Overview

Discover how following the IATF 16949 standard can help you proactively work toward defect prevention and waste reduction in the automotive supply chain.Read More

Partner with our experienced team to optimize your management systems, identify key improvements and stay competitive in the automotive industry.

Our auditors work with the complete supply chain, including manufacturers of parts for production and service, vehicle assembly plants, design and development companies and production and installation organizations.

Our straightforward process for helping you to achieve automotive industry certifications can be completed in these simple steps.

We get to know your organization, its processes, and proposed scope of certification. This may require informational meetings, as well as your application, offer and contract before planning your Stage 1 Audit.

We perform and document your Stage 1 Audit, then create a report identifying areas of concern along with a decision about the organization’s readiness to proceed to Stage 2 and the best timeline. We will send you a report so there are no surprises.

Our Stage 2 Audit is a management system assessment against the requirements of the standard(s) and the organization’s own implemented management system. We will share our assessment report with you, detailing any nonconformities and the timelines required for corrective action implementation and verification. We will thoroughly evaluate corrective measures taken to verify their effectiveness and whether or not the management system meets the minimum requirements for becoming certified.

Once all requirements have been met, you will receive your certification, which is typically valid for three years. Afterward, periodic surveillance audits are conducted, to ensure ongoing conformity of the management system, compliance with relevant interested party requirements and continuous improvement of the management system(s). The certification cycle is a 3-year period, and continued certification requires a renewal at the 3-year mark.

By achieving and maintaining these certifications, your company can help itself better meet its near-term goals and actively identify areas for improvement.

Brand Reputation

Companies that prioritize product quality and operational safety can readily differentiate themselves from the competition.

Regulatory Compliance

Certifying your management systems and processes can help you achieve compliance and reduce risk to regulatory concern.

Cost Savings

From lowering operating costs to protecting the supply chain, companies can better plan for long-term success.