IATF 16949 Overview

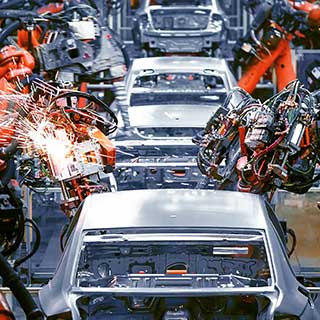

Discover how following the IATF 16949 standard can help you proactively work toward defect prevention and waste reduction in the automotive supply chain.

What is IATF 16949?

IATF 16949 establishes a framework for quality management systems (QMS) in the automotive industry, which is designed to reduce errors and variation in product manufacturing. It is a supplement to the international standard ISO 9001, which applies the same principles to quality management systems in any industry, with specific attention paid to requirements relevant to the manufacture of automobiles and automotive parts.

IATF 16949 Fundamentals

IATF 16949 addresses the factors that drive quality in any organization, aiming to improve process efficiency and effectiveness, prevent defects and variance in the manufacture of automotive parts, optimize the supply chain and ultimately achieve greater customer satisfaction.

However, it is important to note that because IATF 16949 is a supplement to ISO 9001, organizations must first comply with ISO 9001:2015 requirements to achieve certification. The structure of both standards is similar, with headings and section content covering the same topics, making it easier to ensure that both standards are followed appropriately.

Benefits of IATF 16949

Complying with IATF 16949 can help your organization demonstrate its ability to produce/supply automotive products that meet specific customer requirements and fulfill all relevant statutory, regulatory, and safety requirements. Meeting these standards for managing product quality effectively can result in many benefits, such as improved risk mitigation and management, and improved financial performance.

- Efficient Operations: With a focus on continuous improvement, organizations can gain incremental efficiencies through limiting and preventing defects and reducing variation and waste in the supply chain.

- Risk Mitigation: By identifying and addressing risk systematically, organizations can enhance their ability to meet regulatory requirements on product safety, as well as prepare for other risks such as supply chain interruptions.

- Product Quality: Focusing on product consistency and preventing defects can elevate the overall quality of output.

- Customer Satisfaction: Consistently meeting or exceeding customer expectations can lead to marked increases in customer retention.

- Increased Business Opportunities: Certification can indicate your level of dedication to quality management, which can open doors to global markets.

- Enhanced Brand Reputation: Stakeholders, such as staff, customers, and suppliers, increasingly look for a company’s compliance with industry standards as a benchmark for engagement.

- Reduced Costs: With increases in efficiency, costs tend to decrease due to less waste.

IATF 16949 Latest Version

First developed in 1999, the automotive standard has been updated a few times. The latest version of IATF 16949 was published in October 2016 by the IATF and approved by a quality committee of the ISO.

IATF 16949 Revisions

The automotive industry is constantly evolving, and as such, IATF 16949 must also undergo periodic revision to ensure it maintains relevance to new marketplace conditions. From technological advancements to product safety requirements to changing customer expectations, the latest version of IATF 16949 addresses the myriad changes that have occurred since the previous ISO/TS 16949 was published in 2009. Significant changes include:

Risk Mitigation

This version of the standard requires that organizations spend more time in risk-based thinking and planning for risk mitigation.

Customer-specific Requirements

To reduce the number of specialty CSRs, this version requires that traditional CSRs are incorporated into normal processes, thereby increasing consistency across the market.

Product Safety

Additional requirements related to product identification and traceability were added to enhance the recall/repair process, as well as a commitment to safety training and an expectation of safe performance across the lifecycle of the product.

Manufacturing Feasibility

Before implementing operational changes, organizations now must assess the feasibility of those changes first and provide proof of assessment validation with production runs, benchmark studies, and other assessment methods.

Embedded Software

As embedded software has become increasingly common, the standard now requires that if a product contains any, that it be accounted for in product validation processes, warranty management and troubleshooting, along with any customer requirements.

Auditors

The standard now requires that the verification of auditors must be documented, with competencies and approvals proven by the organization.

IATF 16949 Webinar

Gain an in-depth understanding of the tools and techniques used to identify risk for automotive suppliers as defined in the IATF 16949 standard, and review examples of documents used to identify risk.

FAQs

What is the purpose of IATF 16949?

The IATF 16949:2016 structure defines guidelines for quality management systems in the automotive industry. It helps organizations proactively control potential risks and product manufacturing costs and quality effectively, encouraging product safety and continuous value creation.

What is the purpose of IATF 16949?

Who should use the IATF 16949 standard?

Any supplier in the automotive industry, whether large or small, should join the more than 65,000 suppliers worldwide who use the IATF 16949 standard.

Who should use the IATF 16949 standard?

What’s the difference between IATF 16949 and ISO 9001?

While ISO 9001 covers concepts, terminology and requirements for quality management system principles in any industry, IATF 16949 specifies the quality management systems requirements for the automotive industry alone.

What’s the difference between IATF 16949 and ISO 9001?

How does a company get certified for IATF 16949?

To achieve IATF 16949 certification, companies must undergo rigorous third-party assessment. ABS QE is one of the 19 International Automotive Task Force (IATF) contracted certification bodies authorized to provide third-party assessments and IATF 16949 certification.

How does a company get certified for IATF 16949?